| This is

a page about disassembly, repair and reassembly of the Ford (Model B5) FWD

gearbox's as used on the Mk1 (4 speed version similar) and Mk2 Fiestas,

MK3 and Mk4 Escorts and Orions.

The later (Model IB5) gearbox as used on the MK4 Fiestas and MK5 Escorts is

similar but I don't know how similar yet but I'm hoping to get one

shortly for the Quantum.

This page is currently only abut 20% finished and will be spilt into

subpages later.

|

This page was last updated on: .

|

|

Major disassembly.

|

|

|

| Remove 10 cover bolts. |

By the way, this is how to

tell if your gearbox has a LSD

If the hole is nearly driveshaft size right the way through the diff and you can see a

smaller shaft running across

inside the hole it's a normal diff.

If you can see a

small round hole right the way through like this it's a Ford LSD.

|

| |

|

|

Remove reverse switch

(left), and the 2 selector detents.

Don't loose the Detent plungers and springs which may fall out. |

Undo Torx bolt on 5th gear

linkage.

5th gear is this one visible on the top. |

| |

|

|

| Remove circlips from input

(left) and output (right) shafts. |

Lift and remove 5th gear

assy and selector.

Don't let the syncro springs fall out of the hub, they are a bugger

to put back. |

| |

|

|

Remove 5th gears, the input

shaft gear normally needs a puller and can sometimes be very difficult

to get off even with one.

This one was loose and the splines on the shaft are badly worn so it's a bit knackered. |

Remove the 9 Torx screws

holding the 5th gear housing on. |

| |

|

|

| Removing the 5th gear

housing exposes the circlips that hold the input and output shaft

bearings in. |

Move the circlips round so

the end of each circlip butts up against the opposite bearing. |

| |

|

|

| Push the end of each

circlip in the direction of the arrow and catch them when they fly off

across the workshop. |

Circlips removed. |

| |

|

|

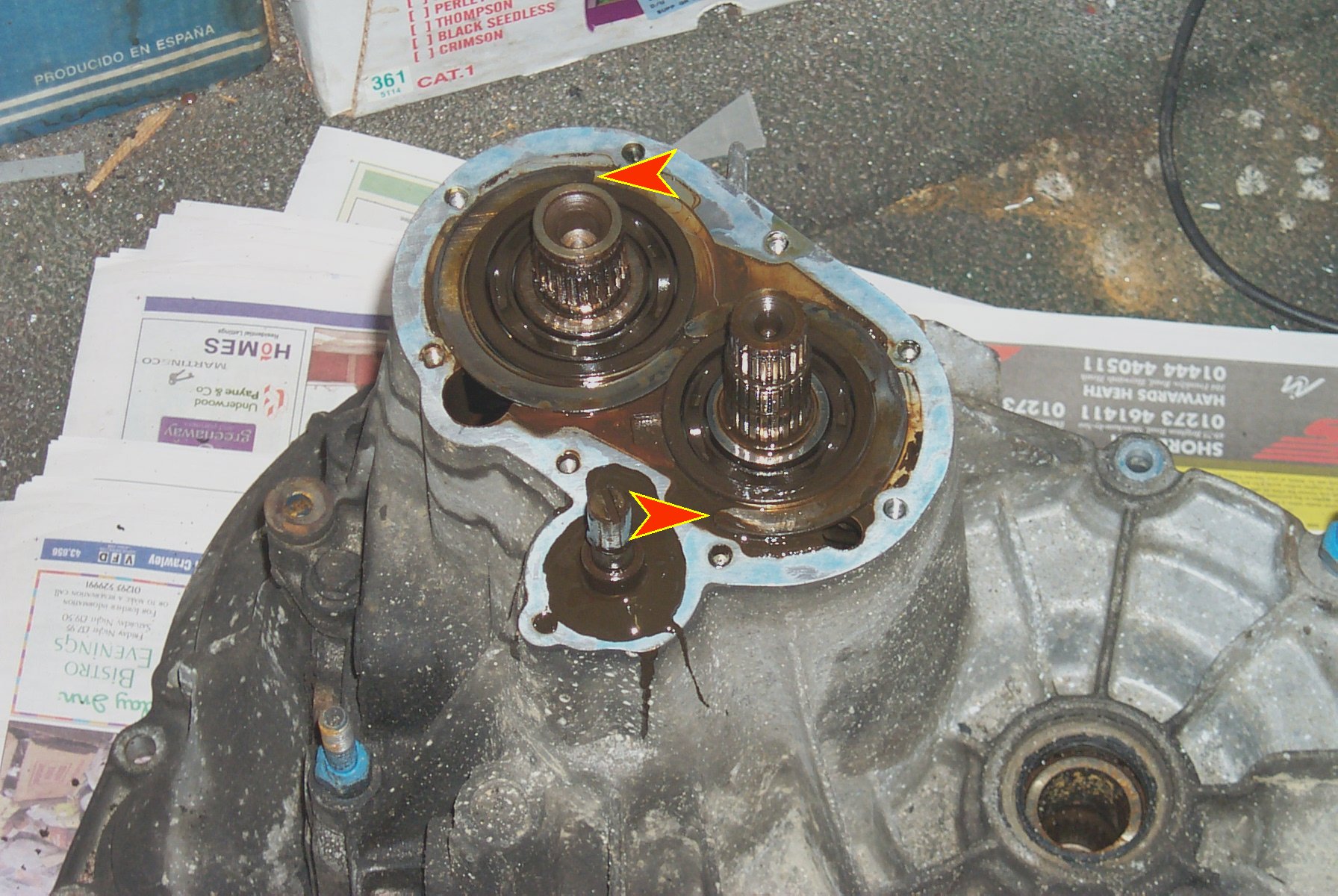

| Remove the bolts and double

ended studs holding the 2 gearbox halves together, the are more around

the back, hidden in the picture. |

Bang all round the edge of

the joint with a hide or rubber mallet until the top half comes loose.

Then carefully lever the top up, only lever where there is a gap

between the 2 castings, where the arrows are, don't lever anywhere else

or you will damage the gasket surfaces. |

| |

|

|

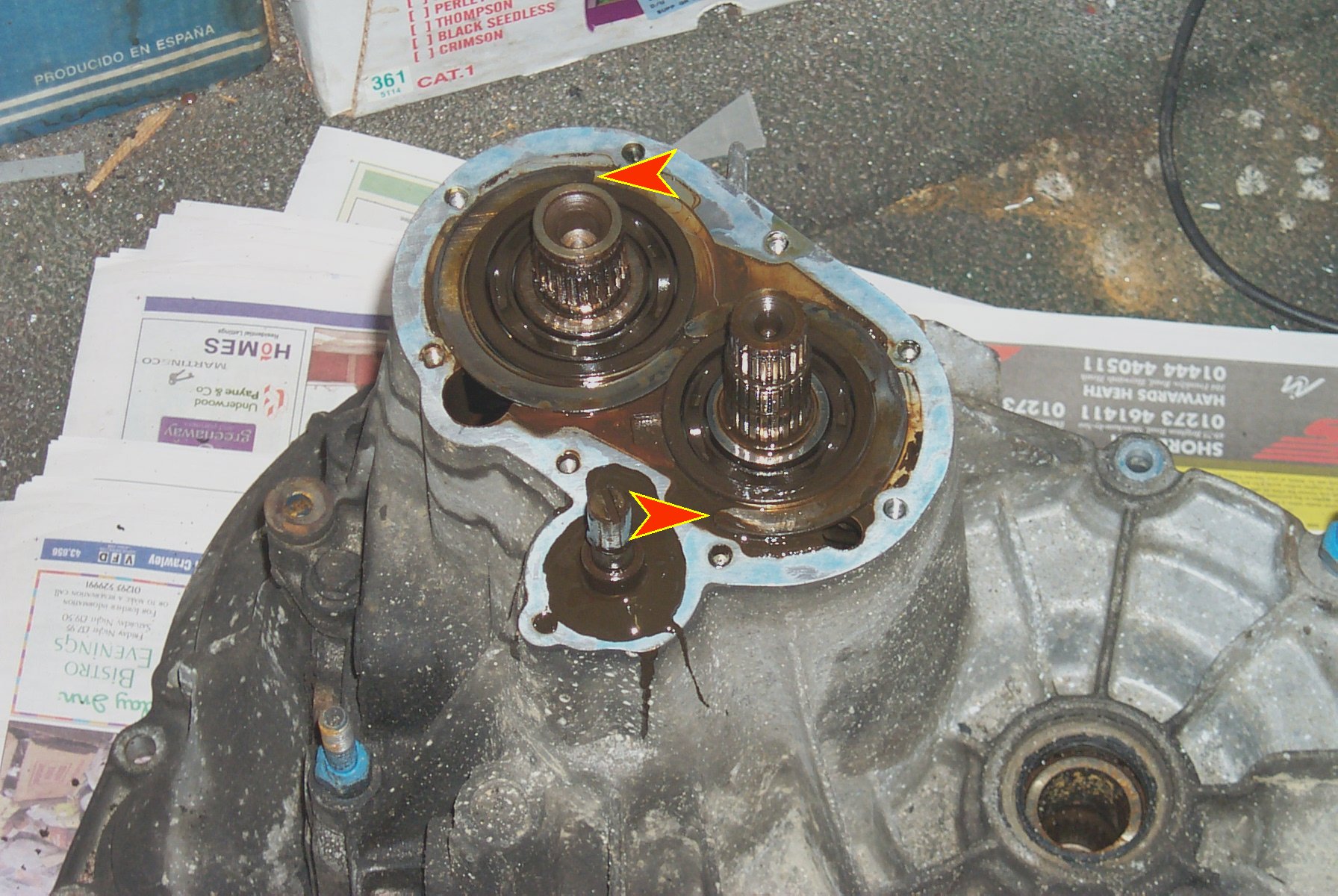

| The housing just separated,

you might need to tap the bearing through the top of the casing as you

lift it. |

Casing removed. |

| |

|

|

| The 1st to 4th gear

selector shaft (arrowed) is a tube which fits over the 5th gear selector

rod. |

The 1st to 4th selector

shaft is retained by 2 circlips. |

| |

|

|

| This is the easiest way to

get the circlips off, push on the 2 ends with a pair of pointy pliers. |

Lift out 1st to 4th

selector shaft.

Grab hold of the input shaft, output shaft and selector forks as one

assy and lift out. |

| |

|

|

| The reverse gear should

lift up and the whole gear cluster should come out like this. |

Lift out the reverse gear

and differential assy. |

| |

|

|

This is why this gearbox

was making a noise, the usual Ford FWD gearbox failure.

The end of the output shaft is used as the inner for the output shaft

roller bearing and the shaft starts breaking up after a while. (left

arrow) |

Close-up of the end of the

output shaft.

The bits of metal flaking off the output shaft get into the other

bearings in the gearbox and knacker them as well. |

| |

|

|

| The differential bearings

have worn so much the diff was rubbing on the gearbox casing. |

All that's left in the

casing is the gear selector mechanism. |

| |

|

|

| Remove the shift lock plate

(left), 5th gear selector shaft (centre) and selector gate plate (right,

you won't have this on earlier boxs). |

Remove guide shaft and

guide lever retaining plate. |

| |

|

|

Remove reverse gear selector.

Undo Torx bolt holding the dog onto the gear change shaft, it's under

the oil somewhere. |

And remove the gear change

shaft and the dog. (this is slightly different on early boxes). |

| |

|

|

| These are the various bits

of the gear selection mechanism. |

And these are all the bits

so far. |

| |